Key Components for Custom Mountain Bike Wheels

“Where do you start?” Before you tweak your custom mountain bike wheel, it’s important to know where to start. This section shall cover the key components you as a rider need to choose to build your ultimate mountain bike wheelsets. Not only customwheelset give you a better experience, but helps you look cooler on the biking trails.

The components you select play a key role in determining the performance of your ride. When you are looking to custom-build, make sure you select every product carefully, from rim profile to hub engagement, and refer to the assembly guide for proper instructions.

1. Rims

The rim is the outermost edge of the wheel that holds the tires and enables its rotational motion. When selecting rims, consider looking for rims that offer good performance, are lighter and stiffer, and are easier to repair.

The rim shapes can vary- the traditional designs were heavier, with U-shaped (box rims) known for their good strength. Double wall-rim features later evolved for more stability and strength in a ride. In the latest rim shapes, we find asymmetrical rims used to balance spoke tension. They also prevent carbon rim damage and provide better wheel strength but at the cost of hub asymmetry.

Many of us are not familiar with how a rim brake or a disc brake are two classic braking systems for your mountain bike. Both braking systems have their usual benefits. It can either reduce your braking friction (disc brakes) or enhance your overall experience with reduced weight (rim brakes). Schmolke TLO 30, Dt Swiss, and other fan-favorite rims are shipped worldwide from the LBS, offering a variety of braking options.

The talk of compatibility does not end here, a wider rim can accommodate wider tires and enhance grip on rugged terrain. When a rider wants optimal riding quality, he should choose an effective rim diameter, and oriented right or left spoke holes, that cut off the tension, and ensure a proper wheel-building process.

2. Hubs

Hubs are the central part of the wheel that connects spokes and allows rotation. You need to be mindful of the role of hubs in custom wheel construction or build for your favorite bike, be it a fat bike, mountain bike, road bike, or gravel bike.

There are parts, like hub shells, flanges (protruding parts, where spokes are attached), axles, and bearings, that allow smooth rotation of the wheels. Since hubs come in various configurations, like front hubs and rear hubs, choose one that provides a drive train when aligning with your bike’s needs.

There are customization options regarding the desired weight, durability, and compatibility with the bike’s frame. It includes axle spacing, free hub type, and rear or disc brake mount compatibility. Overall, hubs, when matched with intended use, can excel in custom wheel building for increased functionality with the rides.

3. Spokes

Spokes are the components in the wheel that connect the hub to the rim. It usually has a tensioned structure that is ideally designed to absorb shock while riding. In the market, the most common type of spoke one can see is J-bend spokes. They are readily most popular with wheel builders, with their easy-to-install and adjust features.

Additional Considerations

1. Weight Vs Strength

There is a myth regarding trade-offs when it comes to the weight and strength of mountain bike wheels. Not all bike types agree with these. The lighter components can also have added durability at higher options, just like carbon and titanium build materials, than their heavy-weighted alloy counterparts.

2. Customization specs

Above, we have talked about rim, hub, and spoke profiles and specifications. You can choose lighter rims and a wheelset that can withstand max spoke tension with better release or thru-axle hub standards with ease of adjustment.

3. Resources

Online tutorials, how-to- guides, and product descriptions—there surely is something you can see in technical specifications. You can also participate in wheel-building workshops if that piques your interest. You buy your hubs, spokes, and rims, or build yourself, while you can also pay for an experienced wheel builder that can assemble it for you.

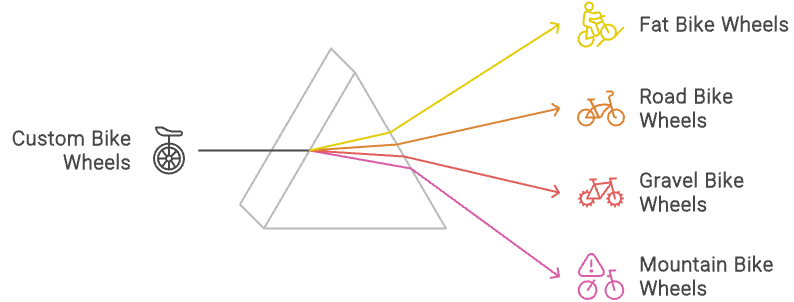

Different Custom Mountain Bike wheels

1. Fat Bike Wheels

E-bike revolution, with that ultimate aim, we help you configure the real-time best upgrades and rides on each type of bike, that too on wheels. It is surprising to see that one of the best fat bike upgrades, with which riders can ease their platform turning, can get extremely affordable if they can research more often.

The front fork of the fat bike soaks up those bumpy feelings on the ride and gives you more controlled riding. With the right fat bike handle wheels and front suspension, you can finally upgrade your wheels.

Here’s how you can start doing this,

- Replace your aluminum rims with better titanium or carbon rims to make it super lighter.

- Your bike loves this upgrade for some level of stiffness and also allows some tubeless rolling.

- Your bike goes fat, and this supports a loose biking trail, with a nimble effect.

Going fat doesn’t have to mean being slow and heavy! This allows you to go tubeless and add some stiffness, making your bike more nimble. In addition, the mud release and inherent stability of the rim make it an absolute upgrade.

For trail testing, there are amazing benefits to them on a snowy or loose mountain biking trail. It can be more than just a winter ride, it’s about a fun year of riding with flat tires with affordable bike upgrades that surprisingly hype up your performance on a fat bike. Some of the most-loved custom fat bike wheels from the Local Bike shop include,

- Wild Dragon Carbon Tri-Spoke Fat Bike Wheel Set

- Black Eagle Carbon Fat Bike Rim

- Drunken Rhinoceros Carbon Fat Bike Wheel and Rim

- Xiphias Carbon Fat Bike Rim

When you shop with the LBS, you get carbon weave, a free coating, matte, and glossy finish material, and at least 32 stroke holes. Which Nextie fat bike wheels have an exceptional profile drawing? That is yet to be figured out.

Let’s demonstrate that a 23lb size XL Carbon LaMere Fat Bike with 27.5 Nextie wheels is the finest option in the budget category. The saddle is not so high, and you are ready to rear on the fat bike wheel custom build. Start pedaling your way through, as the fat bike wheels are the best when it comes to sandy areas.

All of these fat bikes come with options in 26” and 27.5”, and these Nextie custom wheels are bang on. The price starts with the affordable Xiphias 29″ Carbon Fat Bike Rim 55mm NXT29XS55, which is just as good as $310. And the higher-end option nearly reaches $2000.

If you ask, the fat bike rims are often more stable, and the spokes holes are drilled at an angle, which makes the construction more triangular cross-section plus, a right balance between axial direction and radial direction angle, is just the perfect way fat bike riders prefer. The weight of these fat bike custom wheels is super-light starting at 425 g. There are exceptional design features riders can look for when upgrading their bikes.

2. Custom Road Bike wheels

Our ARX 31 mm All Road Carbon Fiber Wheelset is a key performing wheelset with performance and style. For those seeking a timely upgrade in the road bike experience, what else could be better?

The LBS has come up with an exclusive discount on All Road carbon rims ranging from 29 mm to 65 mm, and you can shop these key performance rims for $255. Conversely, If you are looking for a higher-end option to make your ride wow on road bikes, our Disc Wide Road Wheel and Rim combo is a top-tier choice.

Our other hero product is these 25 mm classic road carbon fiber wheelsets for $1180. Not only this, but we are constantly adding to our range of custom wheel builds. So often, check for the latest options while you enjoy hand-built road bike wheelsets.

The stronger aspect of these wheels is the integrally built rim for stronger and more flexible riding. A cyclist can just go Wow with a warranty for as long as 3 years and a bike that matches both needs and has the best price with low charges and worldwide shipping options.

- Road wheels are lighter and made for going smooth and fast, and the construction is different.

- Follow special instructions if you are starting to assemble the custom wheels on your own.

- Be familiar with all the wider rim, disc brake, and tubeless-ready options available on the market.

- Add a free hub body and secure alloy lock nipples in the color of your choice to make your next ride more customizable.

The top suggestion for custom road bike wheel updates includes focusing more on improved acceleration and comfort. One must look for other rider’s preferences when looking for product updates and expansion. Here is what our user has to say,

“I recently upgraded to the ARX 31 mm wheels, and the difference in climbing is beyond surprising. The wheels feel incredibly light and responsive, making it easier to power up even the steepest climbs. Undoubtedly, I trust The LBS, who supply me with custom road bike wheelsets and enhance my overall speed, experience, and efficiency.”

3. Gravel Bike Custom Wheels

Pro-cyclists have often mentioned that the main component is the wheel, but “how do you select the best gravel wheels on your ride?” That we will figure out as we continue. Let’s have a look at some top suggestions for custom wheels for smoother and tricky gravel roads.

- Carbon Gravel Wheelset, 40 mm (Front + Rear)

- Extra Wide Gravel Carbon Rim

- Classic Gravel Carbon Rim

Gravel bikes are all about a versatile bike, and the wheelset is important. Here is a quick guide to see if the wheels of gravel bikes can perform quite well.

- Measure the clearance between the fork and frame to determine the maximum tire.

- Ensure the hub is compatible with your frame’s dropouts and uses thru-axle hubs.

- Look for a custom gravel wheelset that has tubeless rim compatibility and supports at least 32 spoke hole counts.

There are different types of gravel riding, like racing, flow trails, and backpacking, and each has a fun section. If you can effectively choose the right 700 c rims and inner width of at least 23 mm to support the tire requirements, your custom wheel will be a hero assembly.

4. Mountain bike custom wheel

A mountain bike wheel is a tough choice to figure out, given the wide range of options. It’s all about what you prefer as a rider and what experts recommend to shortlist any top 2 choices to finally experiment with or consider buying.

As per YouTuber Evans MTB Saga,

“Building with spokes looks kind of hard; you need to grind out your hub so the spokes do not get cut off at the edges of the hub.”

He elaborated on a situation in his bike upgrade, to which our take was,

“Why pay both sides extra shipping charges when you can custom build your wheels with rims of an internal width of 36 inches or more yourself with professional tips?”

But first, know which rides suit you to finally come up with a mountain bike wheel assembly.

In a lightweight upgrade, you sacrifice strength, right? New hubs from the Local Bike Shop make building wheels completely easy to do without compensating for strength.

Whether it’s your custom hardtail mountain bike or a simple road bike, with every budget angle, you can find accessories, tools, and bike components at the LBS store near you.

Extremely durable, resistant to fatigue, relatively lightweight or custom feature. Even if you are looking for an entry-level budget bike, LBS has you covered.

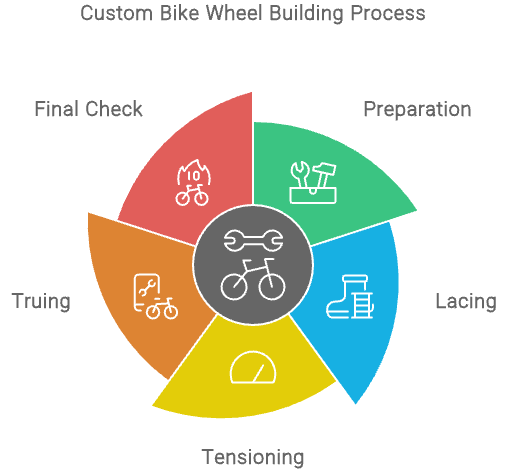

Custom Wheel Building Process in your Bike

“The foundation of any good gravel wheelset is the relationship between the rim and the tire.” with this key point, we begin the custom wheel-building process.

1. Preparation for custom bike wheel assembly

In the custom wheel-building process, there are key steps one can look for. And for the first thing, we need to gather the necessary tools, which include a spoke wrench, a truing stand, a tension meter, a nipple driver, lubricant, and tape.

We also need to buy those materials needed, like rims, hubs, spokes, and nipples, compatible with your bike’s dropout and frame. The preparation part also includes the calculation of the correct spoke length within the effective rim diameter. Later, we dip the threads and attach nipples to the spokes, just arranging everything before lacing up the wheels.

2. Lacing the wheels

Lacing a wheel is a process through which the spokes are fitted into the hub and rim of the bicycle. The lacing pattern may significantly vary between 3-cross and radial based on what you prefer in performance and desired strength in your bike riding. The key steps in this lacing include,

- Place the hub in the center so that the drive side is facing you.

- Insert spokes as per the lacing pattern to align the seats.

- Once all spoke positions are determined, attach them to the rim using nipples.

- Hand tighten the rim first and later tighten it as per preference.

3. Tensioning of the wheel

The custom-built wheel must have structural integrity, i.e., properly tensioned spokes to prevent wobbling and bumps on the wheel. Spoke tension is a crucial thing to be mindful of to distribute load across the rim and prevent spoke breakage during extreme rides.

Since tensioning the wheel can enhance the overall performance and longevity of your cycle, you can not skip out on this step in your custom wheel-building process. This step can help your wheels avoid fatigue and failure over time.

If you are confused about how to measure the spoke tension correctly, you can use a spoke tension meter such as the Park Tool TM-1. To begin with,

- You can try with a reference wheel tension requirement.

- Measure the tension of each spoke to verify the actual tension readings.

- Determine the average tension requirement for the custom wheel build you are trying to create.

Once you are satisfied with the required tension requirement, the initial setup is now tightened with baseline tension and adjusted with a wrench.

4. Truing

The truing process is one of the last steps to getting your bike wheel rolling straight and true. For that, you need tools like,

- Truing stand (recommended; if not, use zip ties on your frame)

- Spoke wrench (the right size as your spokes)

- Spoke tension meter (optional, to obtain consistent spoke tension)

The truing process starts with the initial inspection of tension throughout the spokes and rim. As you continue, you make a gentle ping with your finger and noticeably make the spokes, evenly loosen and tighten as the lateral and radial trues are adjusted.

In this process, you look towards up and down deviation at high and low spots while using the spoke wrench to tighten the spokes. The trick here is to keep it loose on the side opposite the deviation. Our core focus in this step is to identify high at the point and loosen on the opposite side for overall consistent tension.

5. Final check

It’s the final tweak to ensure that your newly installed custom bike wheels are compatible with your riding style. Once the wheel has adequate tensioning and truing, the final step is a test ride, followed by an optimal evaluation of spoke tension.

“Does the wheel spin smoothly or not?” – can tell you a lot. Sometimes a simple test is all you need to get started with the custom wheels. You can recheck the lateral deviation and radial true (roundness) of the wheel.

A smooth spin with no wobbles or grinding noise indicates your wheel is ready for the rough terrain. If not, there are signal problems- that might cause difficulty in handling and riding in any terrain condition. Look for de grove and indicators in rims, and any sort of possible catastrophic breakage before your final ride check.

Conclusion

The LBS, your local bike shop not only helps you to assemble the wheel but supplies essential bike frames, components, and tool kits, at a reasonable rate. Every biker’s dream is our possibility. Tune in for more such interesting blogs and check out our wide range of product selections.

FAQS

Why does a gravel bike rider need wheels with wider rims?

A gravel bike rider has an absolute requirement for a wider rim for better tire performance, lower tire pressure, handling, and comfort. Pro-cyclist recommends wider rims (24mm+) in a custom-built wheel to support high-volume 40-45mm gravel tires and gain stability on gravel cycling. The rims are O-shaped for better traction on loose and slippery surfaces.

Is it Cheaper to Build your own mountain bike wheel?

Building your own mountain bike wheel is definitely cheaper than buying pre-built options, especially when you are planning to get your hands dirty on it.

You can find all the necessary components at an affordable price from the LBS, including spokes, hubs, rims, and nipples. DIY savings can also save on labor costs and help you ensure the wheel cost is truly cheaper.